Welcome to Nutech Refinishing, Inc.

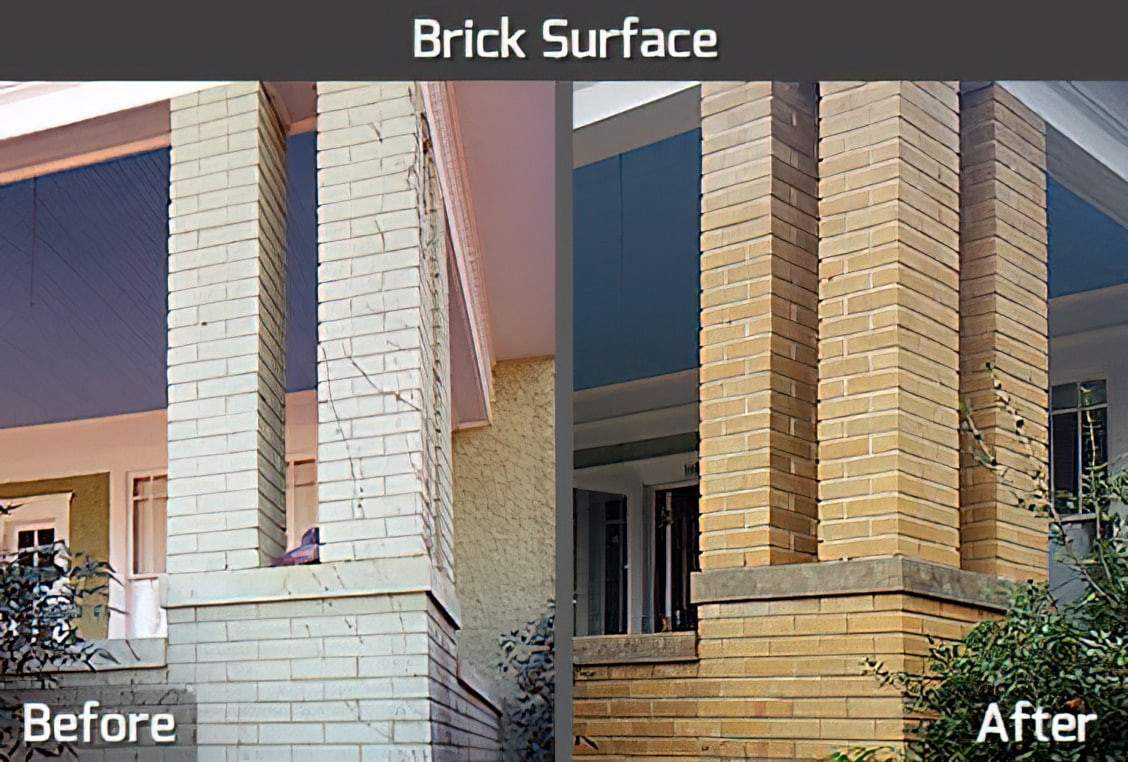

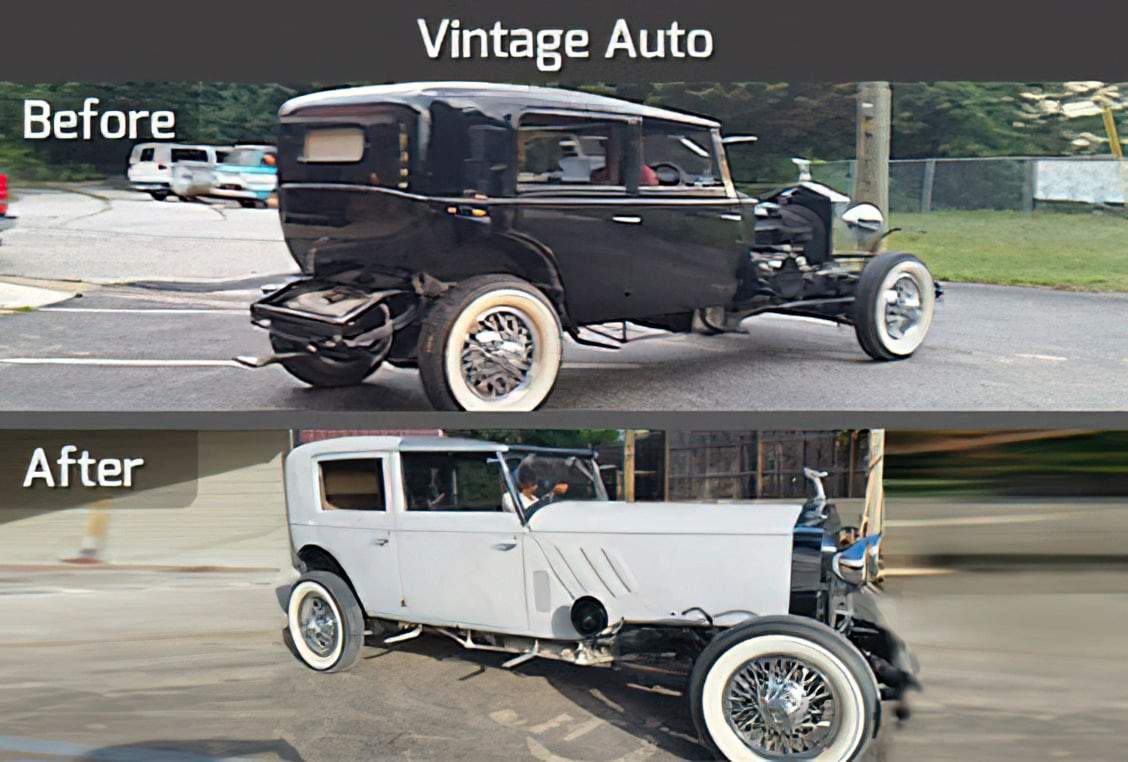

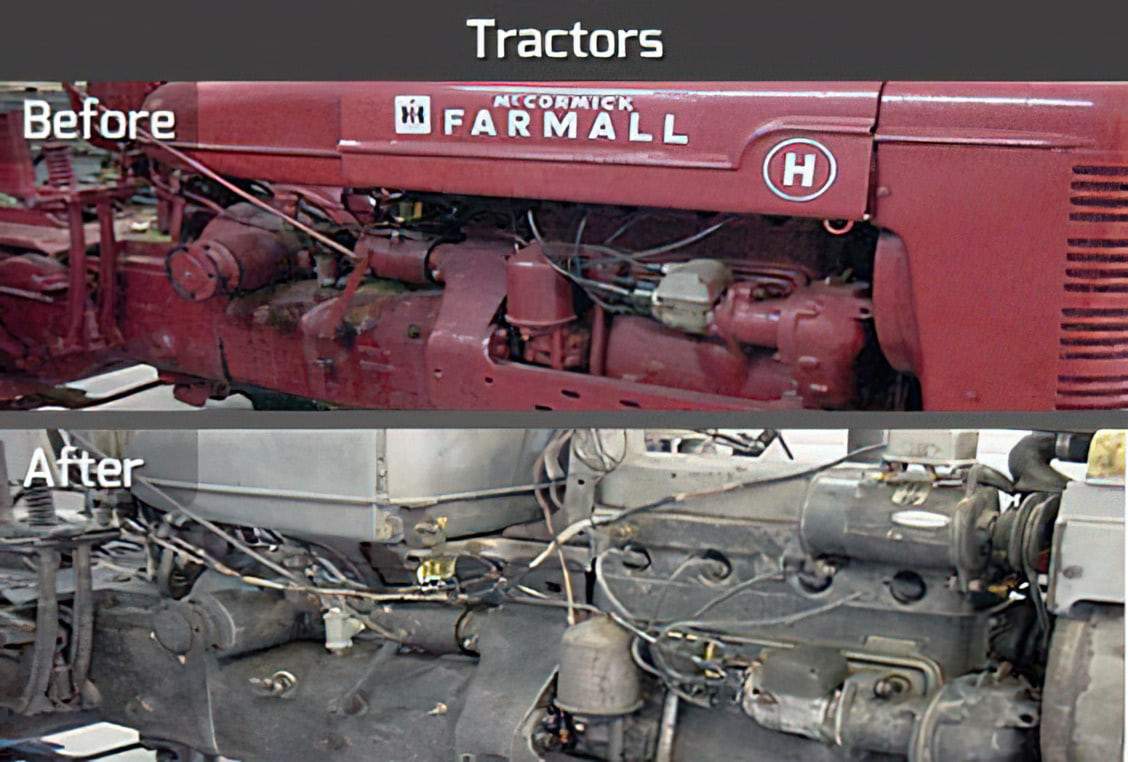

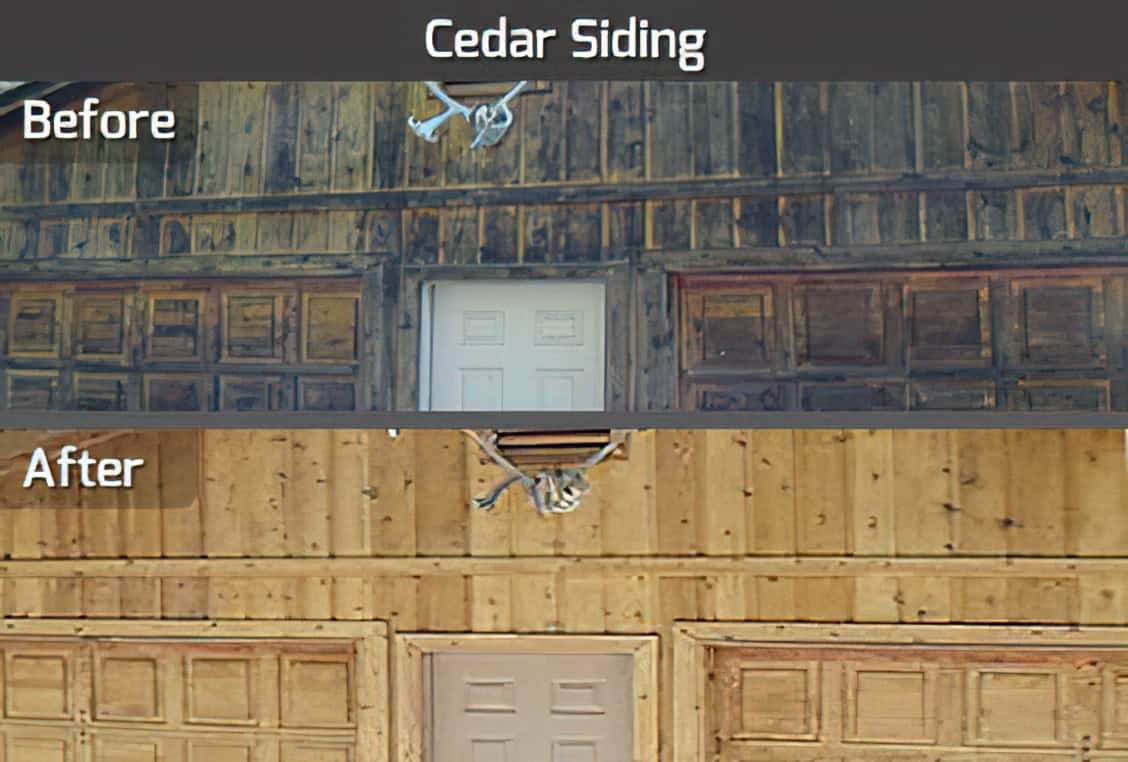

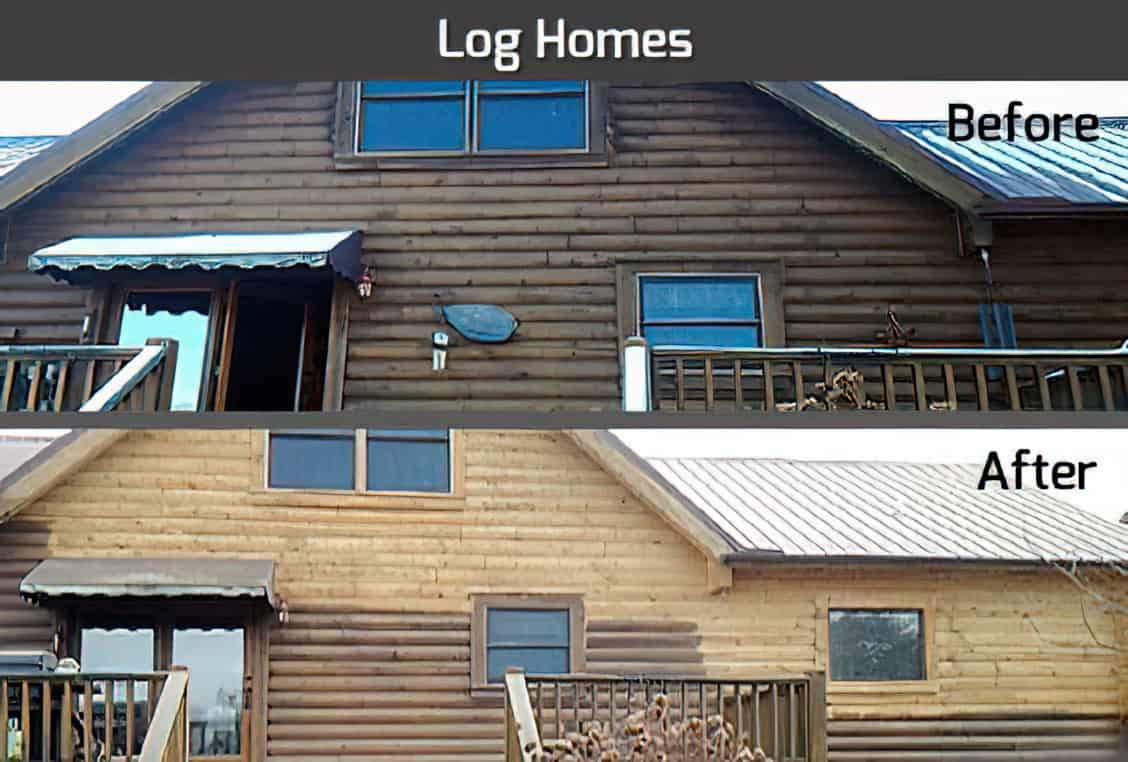

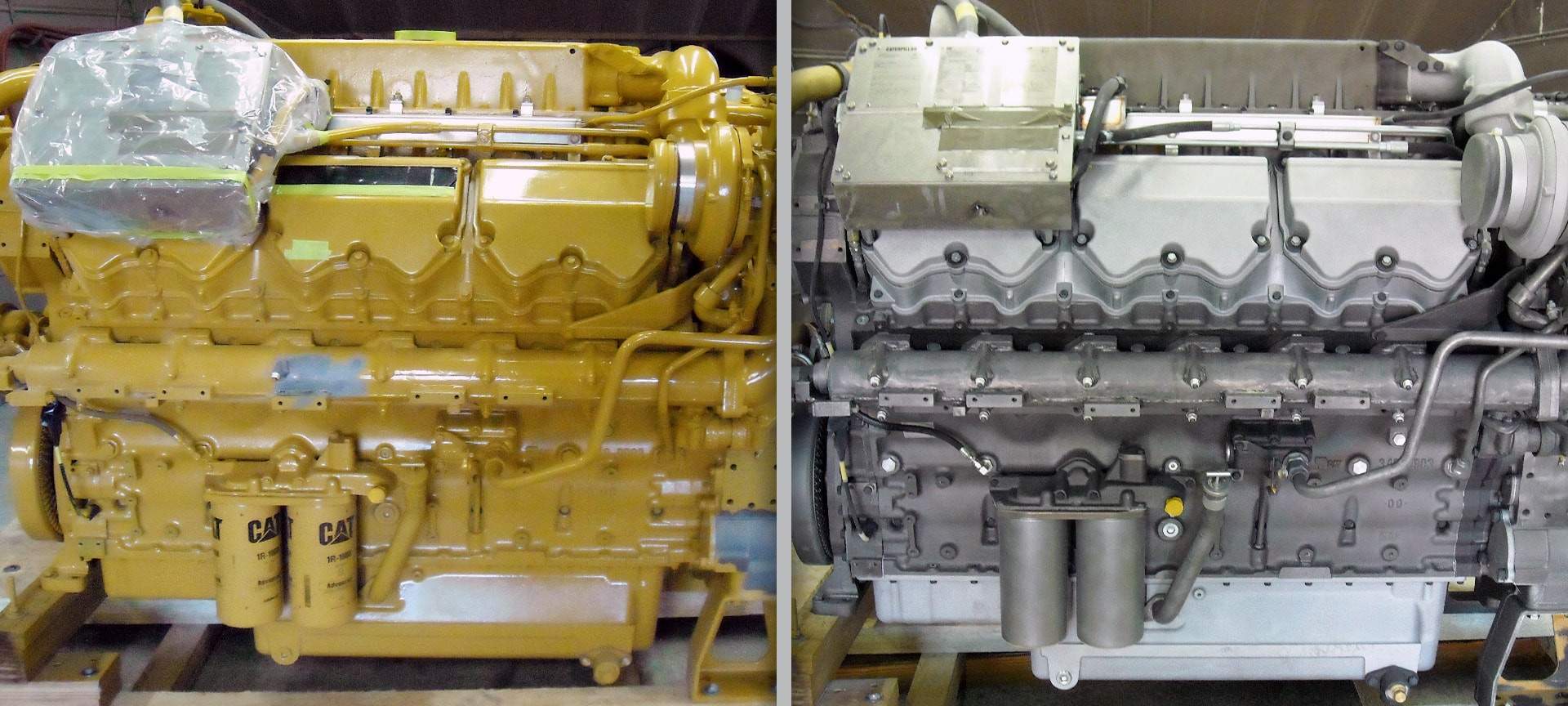

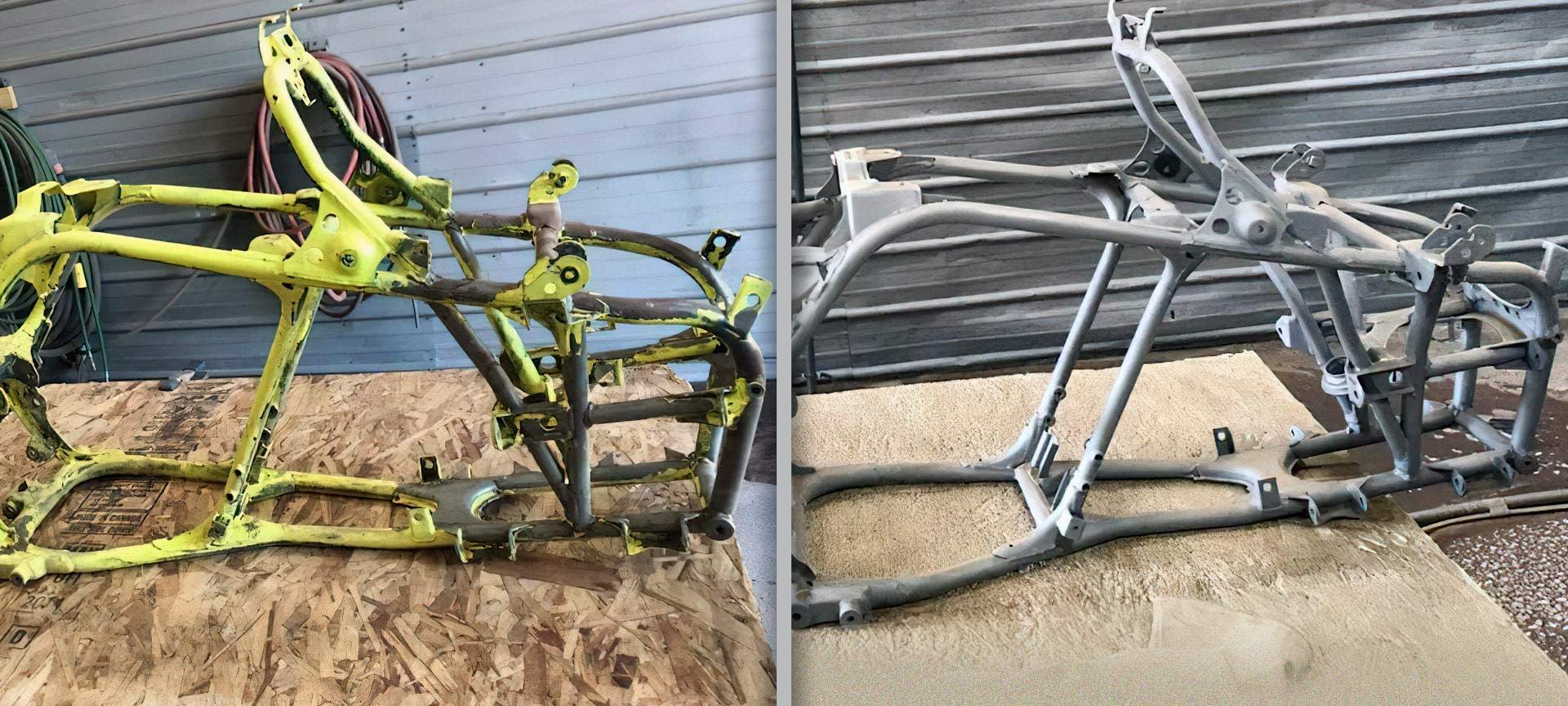

We have over 20 years in the soda blasting industry. Some of the industries that we provide services for is: Mold Remediation, Fire/Smoke Remediation, Automotive Stripping, Industrial Equipment, Agricultural Equipment, Historical Restoration (Paint and Stain Removal), Log Homes, Food Processing Plants and Equipment, Restaurant Equipment, and etc.

Soda Blasting, sometimes referred to as Baking Soda Blasting, is a process using a Food Grade Soda Bicarbonate applied with air pressure than can strip most coatings from numerous substrates without damage. Soda Blasting easily removes paint, coatings, grease, oils, gasket material, surface corrosion, mold and fire/smoke damage from a variety of substrates like stainless steel, aluminum, alloys, plastics, fiberglass, carbon fiber, glass, wood and composites without damage or distortion. Soda Blasting leaves hard anodized coatings intact and on most hard surfaces with no profile.

Soda Blasting is Green Technology

Before Soda blasting arrived on the scene, the only way you could remove paint, body filler or some other unsightly material from a contaminated surface, was to either chip it off, sand it, use harsh chemicals or sand blast it. Now there is SODA BLASTING . Soda Blasting, sometimes referred to as baking soda blasting, is a process that can strip almost any surface in an efficient and safe manner, our machines can also be modified for Dustless Soda Blasting. Although it is similar to traditional sandblasting, it has the significant advantage of cleaning the surface without causing harm to the substrate or the environment. Soda Blasting easily removes paint, coatings, carbon, grease, oils, gasket material and surface corrosion from a variety of metals, alloys, plastics, fiberglass, carbon fiber and composites without substrate damage or distortion. Soda Blasting leaves hard anodized coatings intact.

Looking for Soda Works Equipment, Parts, or Natrium Soda?